Free shipping on all US orders

10% OF OUR PROFIT GOES TO KIDS’N’CULTURE NON-PROFIT ORGANIZATION

The process of 3D printing operates differently from traditional woodworking and metalworking because it uses an additive method to construct objects through sequential layer construction instead of subtractive methods which require material removal to achieve desired shapes. The development of 3D printing technology started during the 1980s when Dr. Hideo Kodama from the Nagoya Municipal Industrial Research Institute created an early additive manufacturing method which used photopolymer to build three-dimensional models through sequential layer formation.

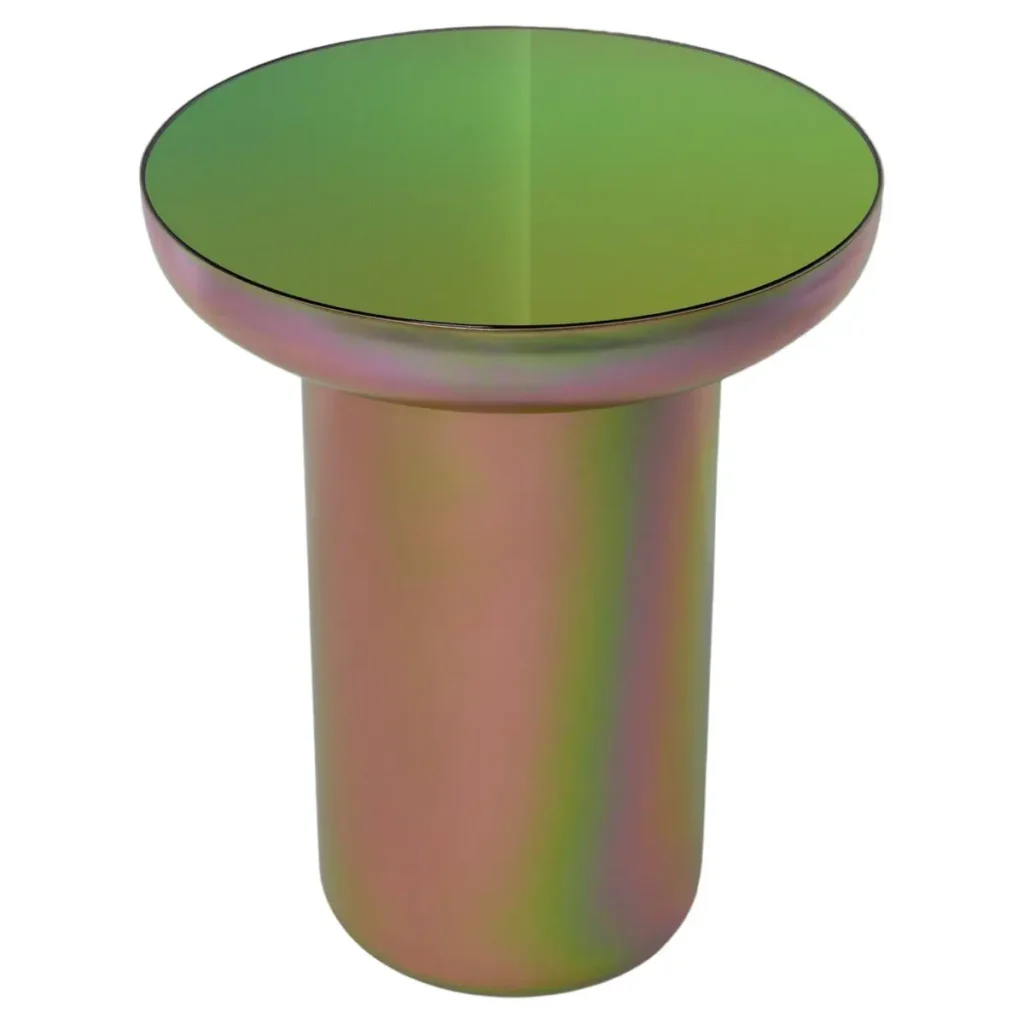

The digital 3D model (CAD) serves as the starting point for this process. The file gets transmitted to a big printing machine which uses a nozzle to print material while following the exact path that the computer system has defined. The process results in a complete functional piece of furniture which appears as a single continuous object within a short time frame of hours or days.

3D-printed furniture has multiple uses because manufacturers now offer a wide selection of materials which serve design purposes. The market leads with PLA (Polylactic Acid) because it offers simple operation and it comes from plants. Designers select PETG and ABS materials for their high durability and heat resistance needs but they choose Nylon because of its exceptional strength-to-weight performance and flexible properties which suit interlocking joint applications.

The production of wood-filled filaments which combine 70% PLA with 30% recycled sawdust, enables the creation of chairs and tables that duplicate the appearance and texture of natural wood while releasing its characteristic scent. The industrial and architectural sectors use concrete 3D printing to transform outdoor furniture design, while metal-filled composites and carbon-fiber-reinforced polymers enable the production of weightless high-performance items which were beyond manufacturing capabilities.

The environmental impact consists of two separate elements.

There are no reviews yet. Be the first one to write one.

A whole world on the tip of a pencil. The story of an artist who proved that true art has no limits and that it is never too late to start all over again.

International fashion icon and symbol of Parisian style, Ines de la Fressange is one of the most famous women in France.

Anastasia Pilepchuk is a Berlin-based artist with Buryat roots. She creates masks and face jewellery inspired by the nature and the culture of her beautiful region.

A whole world on the tip of a pencil. The story of an artist who proved that true art has no limits and that it is never too late to start all over again.